machining surface finish ra

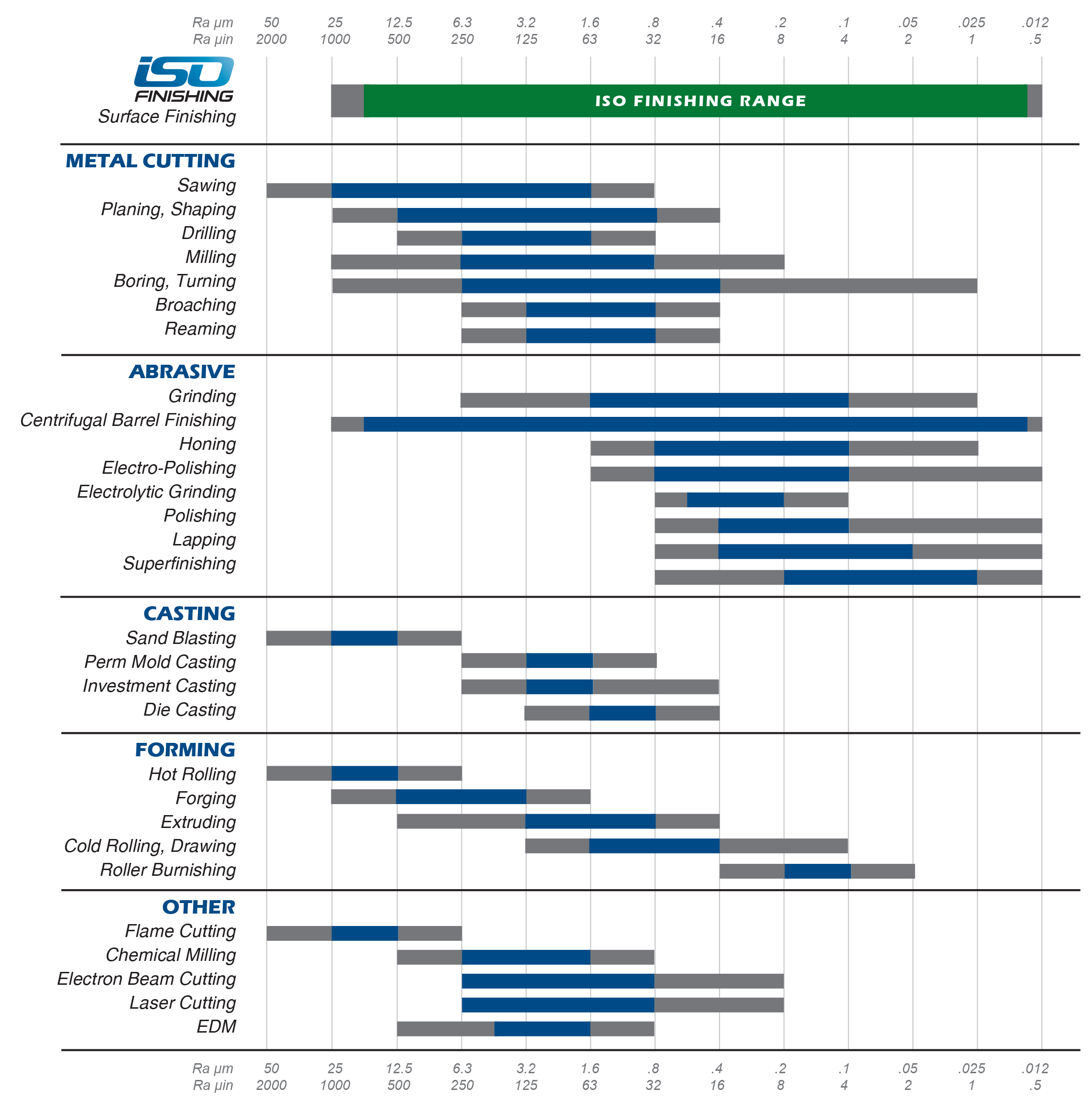

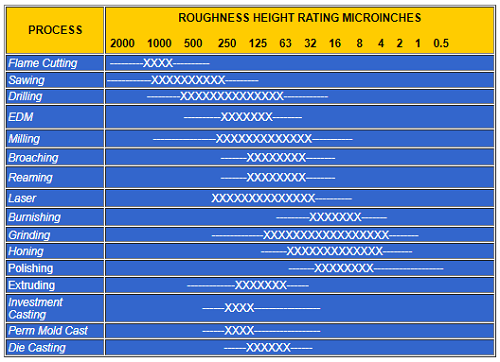

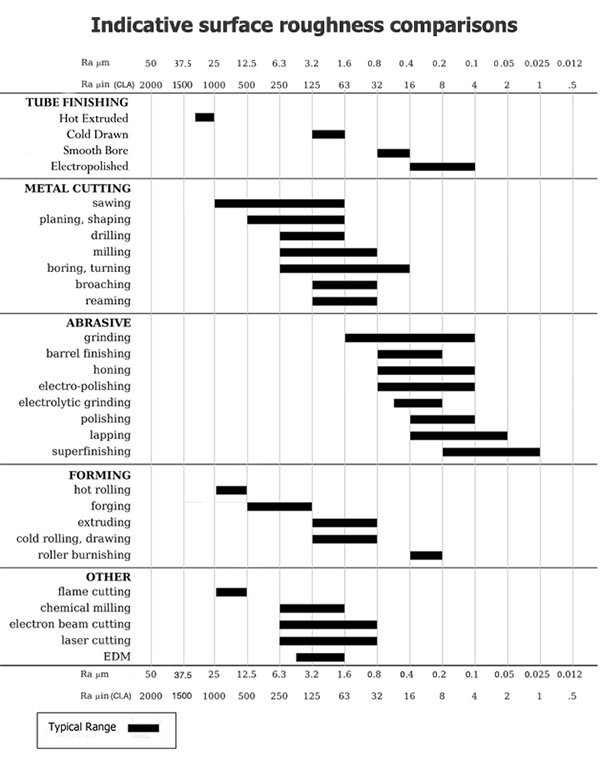

RA Surface Finishes for Various Manufacturing Processes There are several industrial processes manufacturing companies execute to fine-tune the surface of their products. Surface Roughness Produced by Different Manufacturing Process.

Surface Finish Specifications And Their Hidden Cost Impacts Keller Technology Corporation

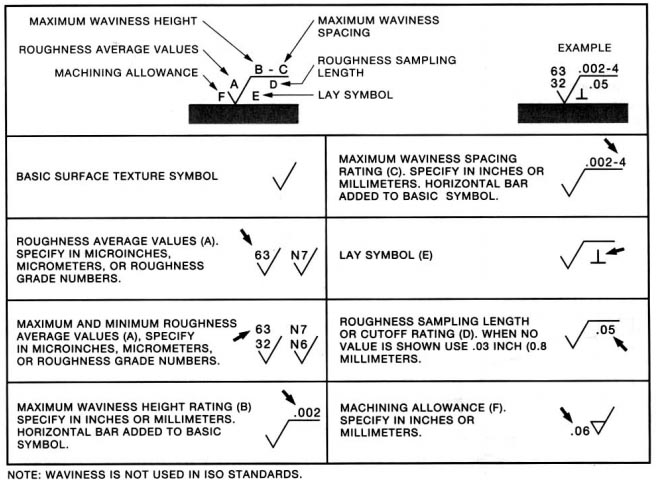

13 rows When you search for machining surface finish symbols on your favorite browser you would.

. 32 μm Ra It is the typical finish for. Determining the surface roughness is the first step that should occur after plastic parts are machined. These units help design engineers as well as technicians to understand.

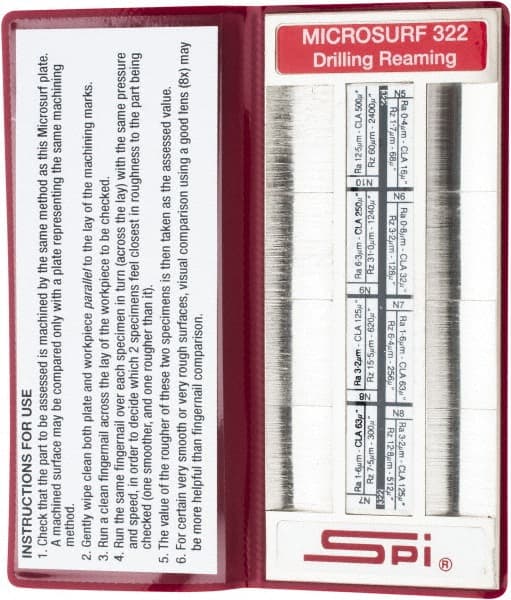

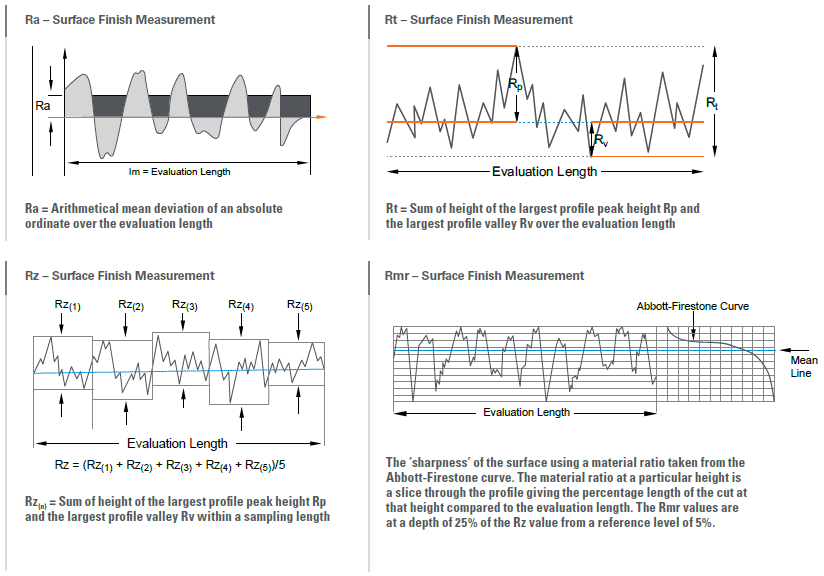

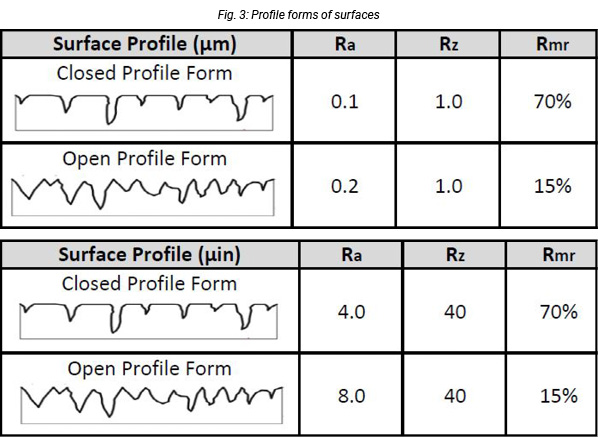

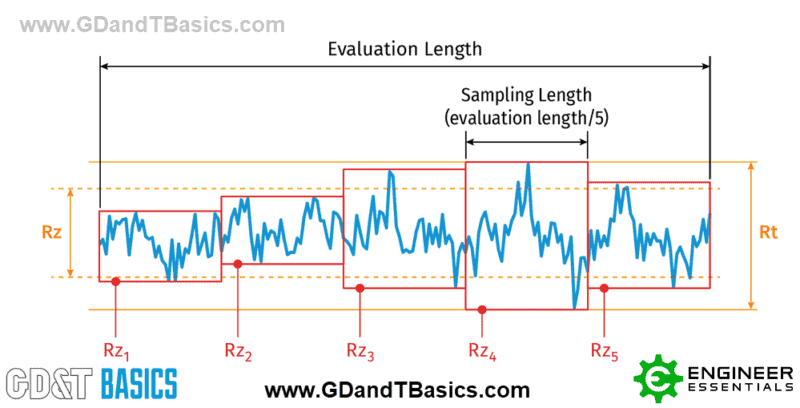

This is done by breaking the total measuring. We will discuss below the typical surface roughness units in use in the machining world Ra Roughness Average Ra is the most commonly used unit. Surface finish specification and comparison.

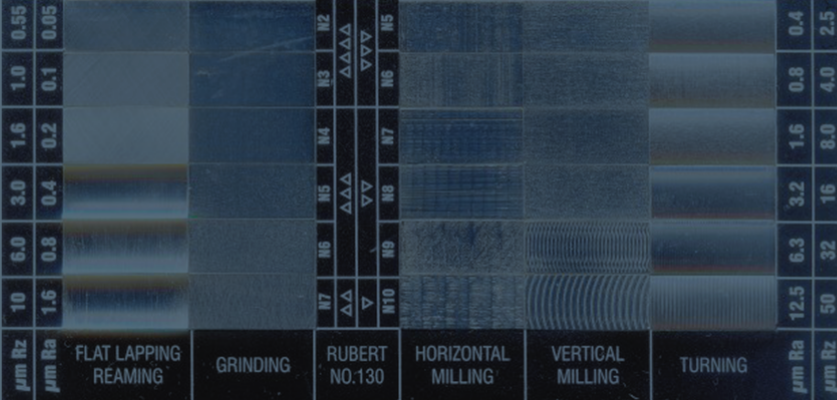

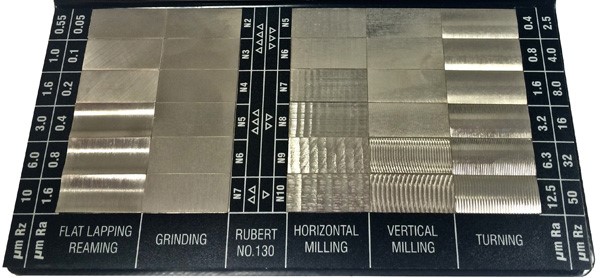

N1 1 0025 Lapping. This is done through measurements by using a unit known as Ra. Finish Symbol N Finish R a μinch R a μm Super finishing.

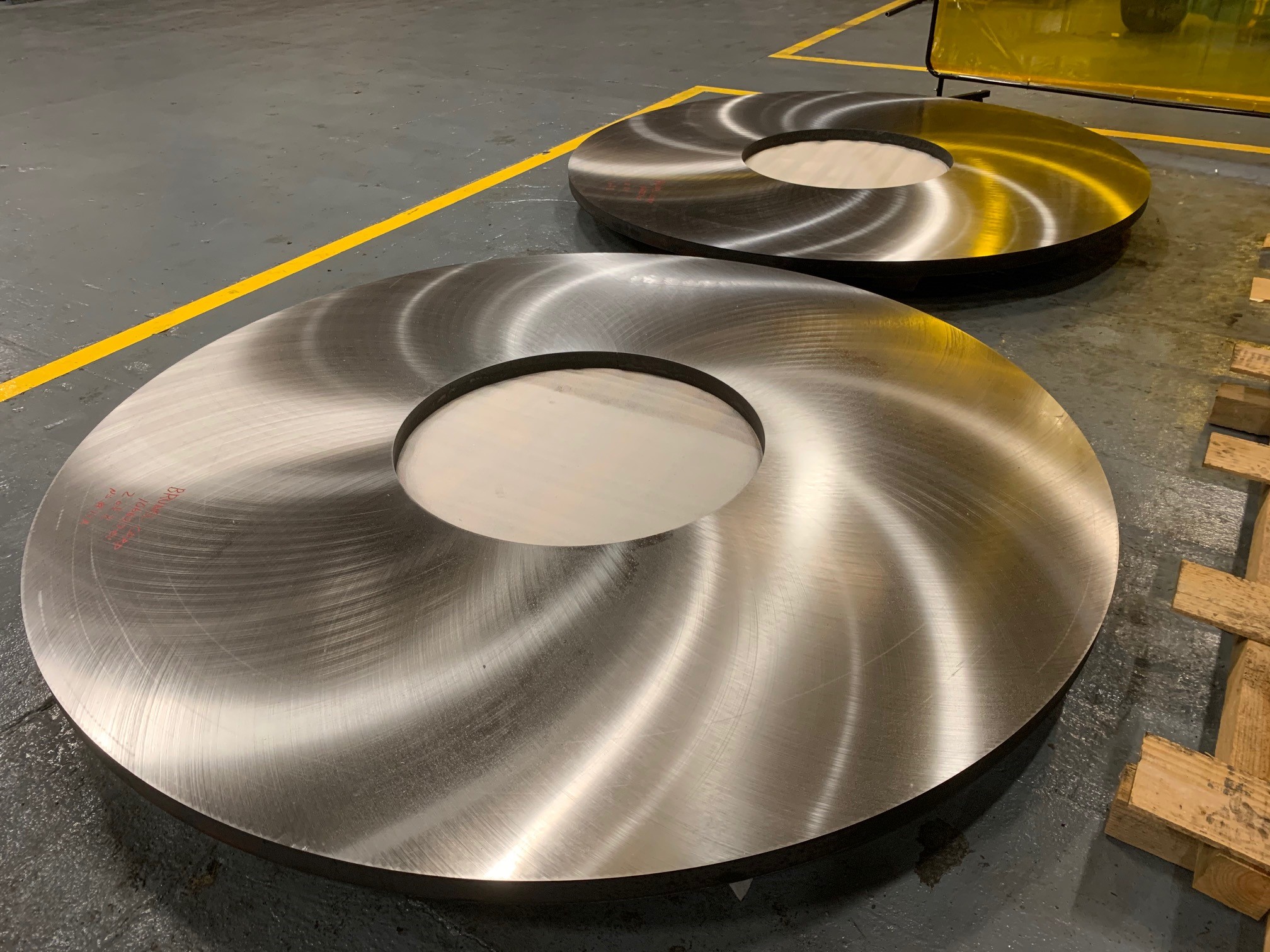

The lower the Ra value the more machining effortoperations necessary hence quality control. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an. 1 Surface Finish.

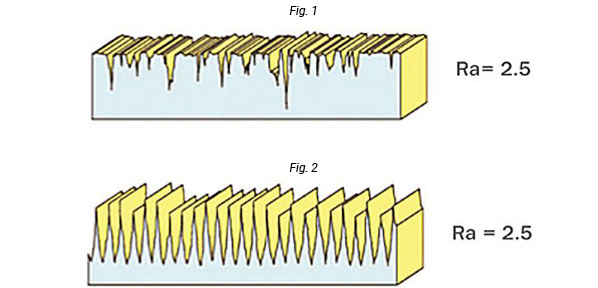

First of all what do we mean by surface finish. When measuring surface roughness the first step is to filter out the waviness component from the roughness component. Surface roughness significantly affects the functionality performance and durability of parts in certain.

Below are listed some of the Ra values. The roughness of the surface finishing determines how the surface lines and surface quality of the part will appear after it has been machinedSurface finishing means how a mechanical. What is Ra.

According to ASME B461 Ra is the. Surface finish is simply the condition in which you find the surface of a part at any point during the. According to an article in Modern Machine Shop written by George Schuetz director of precision gages at Mahr Federal Ra is calculated by an algorithm that.

Surface roughness for CNC milling and turning compared. The surface finish of a machined part is described using some parameters which are called surface finish units. 10 micrometer Ra x 87 Rt Factor 87 micrometer Rt 40 microinch Ra x 87 Rt Factor 348 microinch Rt Surface Roughness Value Equivalents The Waviness is the measure of.

Machining N9 250 63 N10 500 125 Rough.

5 Grinding Considerations For Improving Surface Finish Norton Abrasives

Steel Surface Finishes Precision Grinding Inc

What Metal S Surface Finish And Surface Roughness China Piping Solution Supplier China Piping Solution Supplier

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Roughness Chart Comparison Iso Finishing

Surface Roughness Finish Review And Equations

Image Of Surface Finish Under Microscope A Surface With Ra 20 Nm B Download Scientific Diagram

Vdi 3400 Surface Finish Edm Surface Finish Chart Upmold

Beyond Ra Why Surface Finish Matters In Seal Performance Fluid Power Journal

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Spi 0 4 To 12 5 Ra Micro M Surface Finish Nickel Surface Finish Comparator 06558225 Msc Industrial Supply

Selecting Right Surface Roughness For Cnc Machining Xometry Europe

Surface Roughness Finish For Bearings And Seals Hallite

Beyond Ra Why Surface Finish Matters In Seal Performance Fluid Power Journal

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Shop Tips 293 Surface Roughness Finish 1 Of 2 Tubalcain Youtube